Grace plastic injection mold Basic types of gates for plastic injection mold

December 11, 2023 IN3DTEC Comprehensive Guide to Injection Molding Gates Introduction: Injection molding is a widely used manufacturing process for producing plastic parts with high precision and efficiency. A critical aspect of successful injection molding is gate design and placement.

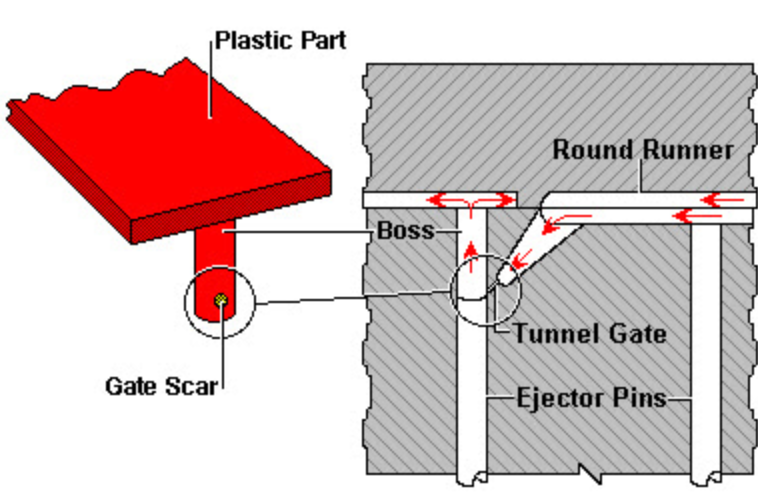

Tooling Tunnel Gates for Mold Designers, Part 1 Plastics Technology

Texturing is a process used to apply patterns to a mold surface. This process allows flexibility in creating the final appearance of your parts. Texturing is an integral piece in overall product development and should be considered during the design process to achieve the desired results.

Plastic Injection Molding What Is It? How Does It Work?

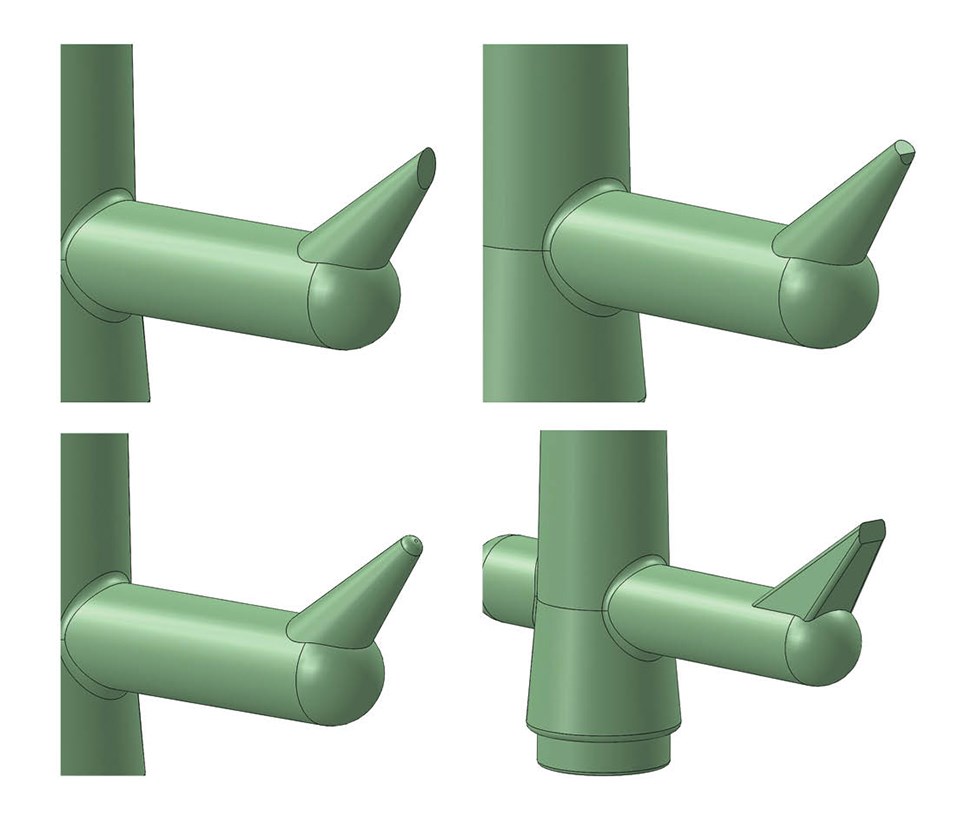

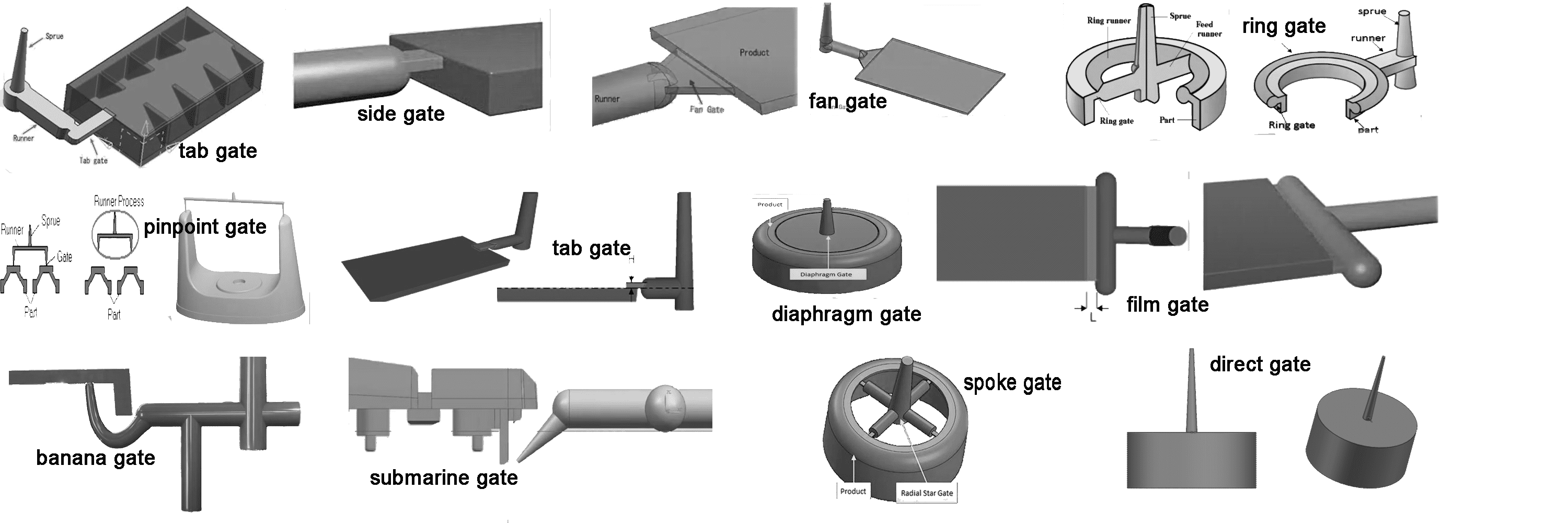

Because of this, it is important to know how to use gates before starting an injection molding project. This article looks at six of the most common gate types used in injection molding: edge gates, tab gates, direct/sprue gates, hot tip gates, pin gates, and sub gates. It looks at the properties of these unique gate styles and offers.

6 types of injection molding gate & when to use them

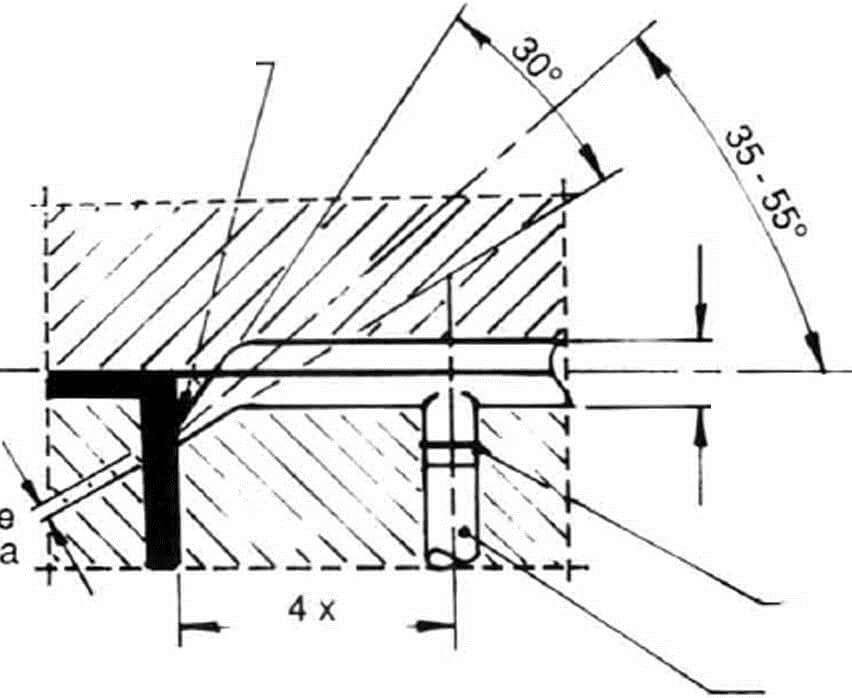

4 Jan 2024 Updated 7/8/2022 Published 1/2/2018 Tunnel Gates for Mold Designers, Part 1 Of all the gate types, tunnel gates are the most misunderstood. Here's what you need to know to choose the best design for your application. processing tips Tooling Know How best practices Tooling Know How Molds & Tooling Jim Fattori Founder Read Next

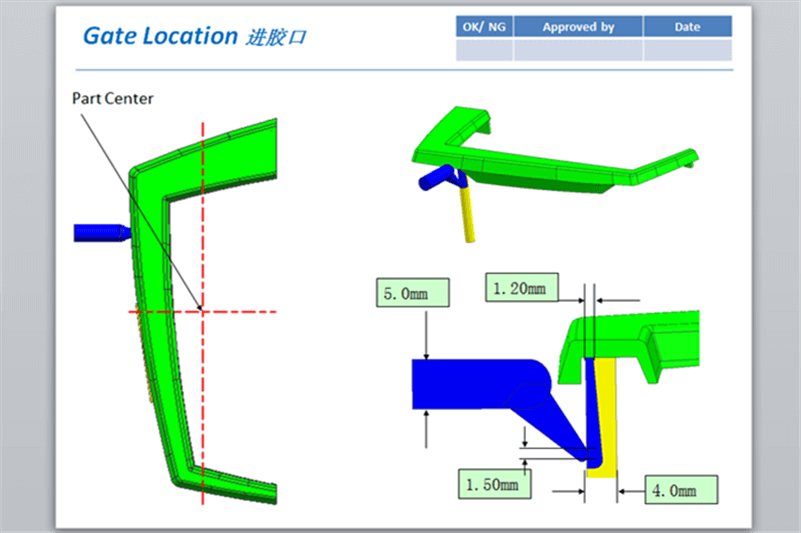

Injection Molding Gate & Gate Design Plastopia

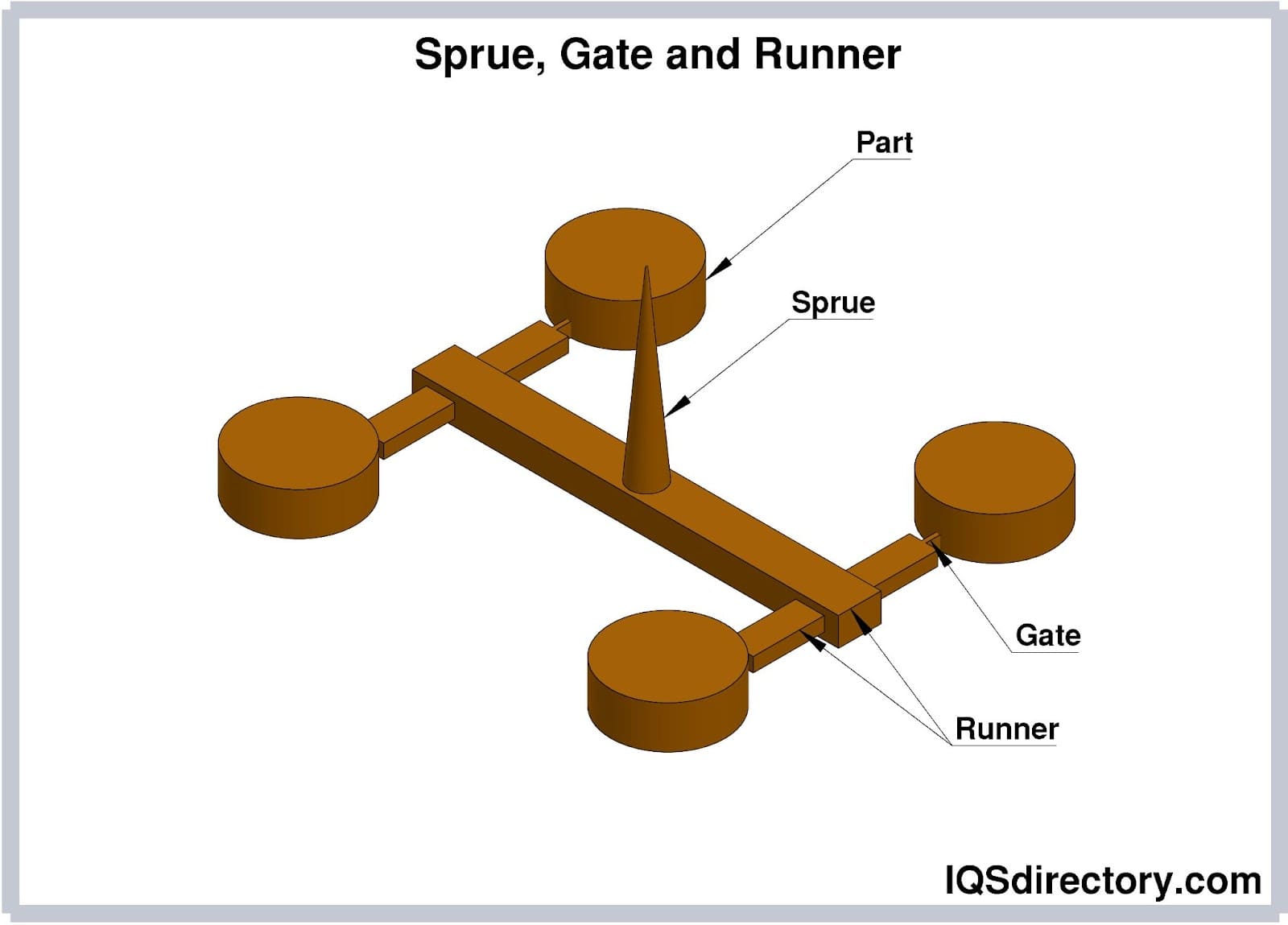

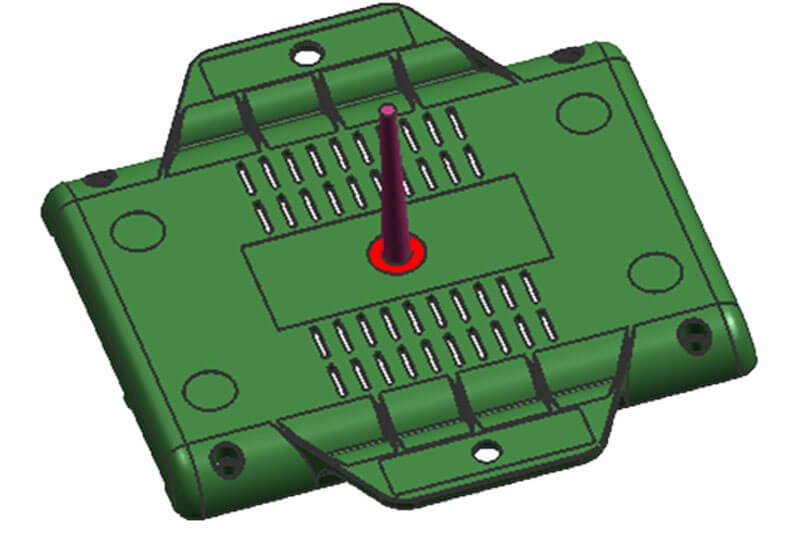

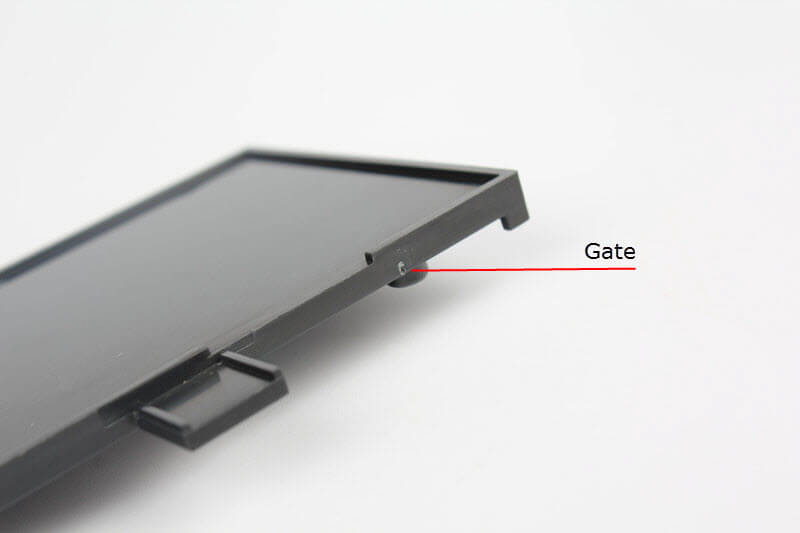

The "gate" is the opening in a mold through which the molten plastic is injected into the final part. It is the boundary between part and scrap. The location, size, and shape of the gate can have a significant effect on everything from the structural integrity to the visual appearance of a finished piece.

9 Kinds Of Gates Design For Plastic Mold BuildingTopworks

Injection Molding Gate Issues Caused by Improper Material, Size and/or Location. In plastic injection molding, gate design is critical to achieving molded part quality and productivity. Because gates are designed to allow melted plastic resins to move into the mold cavity, it's imperative that gate material, size and location are optimized.

1964 1967 Vista Cruiser Ribbed Tail gate molding

Gate design | AMILAN™ | TORAY PLASTICS | TORAY Consider whether each shot yields one or multiple parts. Assuming commonly used runners, try to achieve gate balance by adjusting the cross-section surface area of each gate to accomplish uniform filling. < Exercise >.

Injection Molding Gate & Gate Design Plastopia

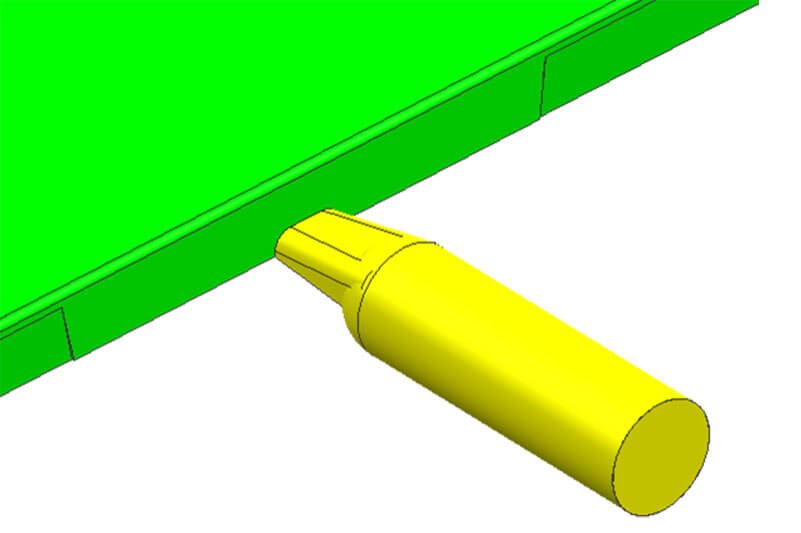

Side gate injection molding is a process used to create plastic parts. Molten plastic is injected into a mold cavity through a gate located on the side of the mold. This type of gate offers many benefits over traditional gates, such as runner systems or sprue gates. Some of the benefits of using a side gate include:

Injection Molding Gate & Gate Design Plastopia

Updated: November 11, 2021 Tools for injection molding may be hard to design or manufacture. However, they have basic concepts which are easy to understand. An injection molding gate system helps to direct the molten plastic from the nozzles of molding machines. This is a gateway of the plastic into the core of the tool.

How to Optimize Gate Locations to Improve Moldability (NA) On_demand_webinar Moldex3D

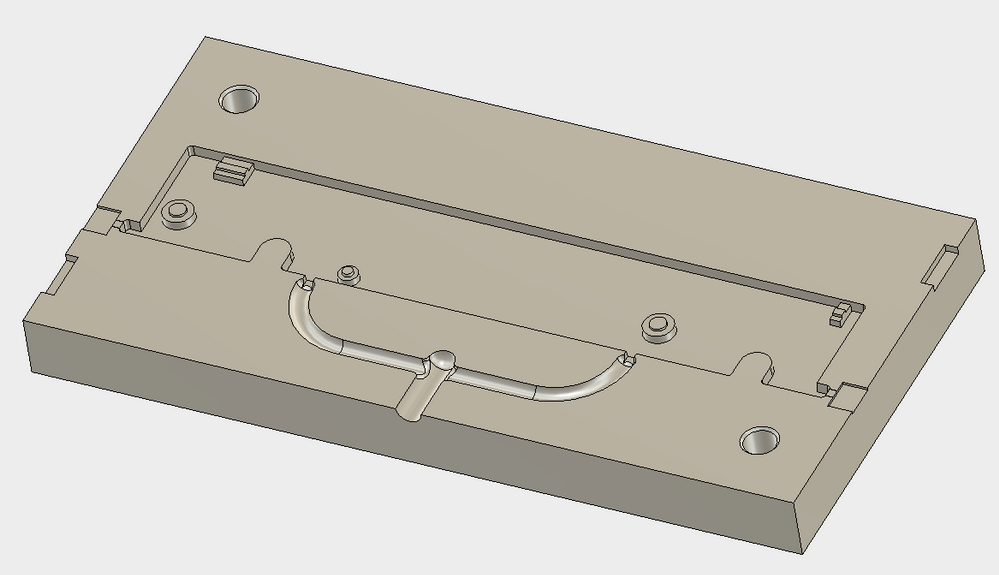

Molding Guidelines Gate Design The gate serves as the entrance to the cavity and should be designed to permit the mold to fill easily. A cavity can have more than one gate.

Injection Molding Gate Location 5 Tips To Choose The Right Gate Location For Mold

Edge gate, also known as side gate or rectangular gate, is commonly used in injection molding. It receives its name because it typically undergoes processing to shape it into a rectangle. The gate is usually located on the parting surface and feeds from outside the cavity.

Pin by Full House on Moldings & Millwork Wooden doors interior, Interior door trim, Doors interior

The following should help you along the way. Avoid obstructions like pins, cores, and sidewalls that may end up impeding the flow of plastic being injected into the mold. Keep gates away from any form of obstructions. Ensure that the area around the mold gate is well strengthened as it will be subject to a lot of pressure and stress.

9 kinds of Gates design For Plastic Mold BuildingTopworks

Gate Location and Warping Center gate: radial flow -severe distortion Diagonal gate: radial flow -twisting End gates: linear flow -minimum warping Gate Air entrapment Edge gate: warp free, air entrapment Sprue 2.0 2.0 60 Before shrinkage 60.32 1.96 1.976 After shrinkage Shrinkage Direction of flow -0.020 in/in Perpendicular to flow -0.

Injection Molding Gate & Gate Design Plastopia

Using the proper injection molding gate can guarantee the quality of your molded components. The amount, pressure, and temperature of the molten plastic in the injection molding process are affected by parameters such as gate type, position, dimensions, material, and mold type. Injection mold gate design is used in several sectors to create.

An Ultimate Guide for Injection Molding Gate Design RapidDirect Blog (2022)

May 21, 2021 3 min read What Is An Injection Molding Gate? A gate is a small opening in the tool that allows molten plastic to enter the mold cavity. Gates are a critical aspect of mold design because the location, number, and type will affect cosmetics, cycle times, and part features.

design sprue gate direct gate in injection mold Mechanicaleng blog

Gates in plastic injection molding refer to openings through which molten plastic passes to enter the mold cavity. As the name suggest, they serve as gateways - passage - for liquid plastic components to enter the mold cavity. Injection molding gates occur in different forms, taking distinct sizes and shapes - appearing narrow, wide, tapered, etc.